TPPL battery: Thin Plate Pure Lead (TPPL) batteries are a type of lead acid battery which have electrodes that are thinner than traditional lead acid battery designs. TPPL batteries have a high rate of charge and discharge which increases the level of internal heat. This causes the life of a TPPL battery to deplete faster than other types of lead acid batteries.

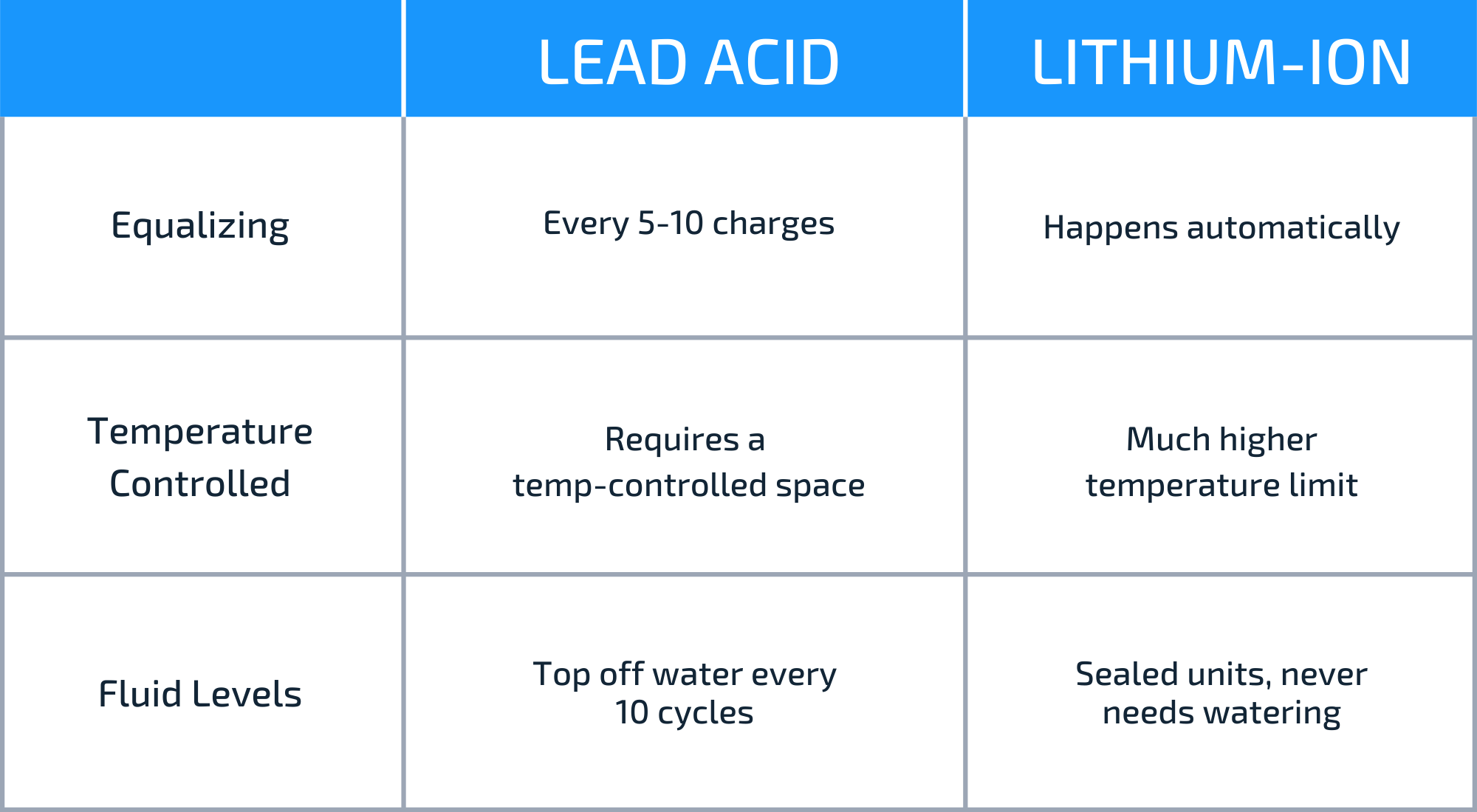

Flooded battery: A flooded battery has plates, separators, and a high-density paste material. It uses a liquid electrolyte that submerges the plates. The liquid solution can be damaged in extreme temperatures due to evaporation or freezing. This requires watering and maintenance of the battery.

Battery anode: The anode is the negative electrode in the cell. It is very common, in lithium-ion batteries, for it to be composed of lithium and carbon, usually a graphite powder. The current can be collected due to the copper film that is combined with the electrode. The purity, particle size, and uniformity of the anode all contribute to the aging behavior and capacity.

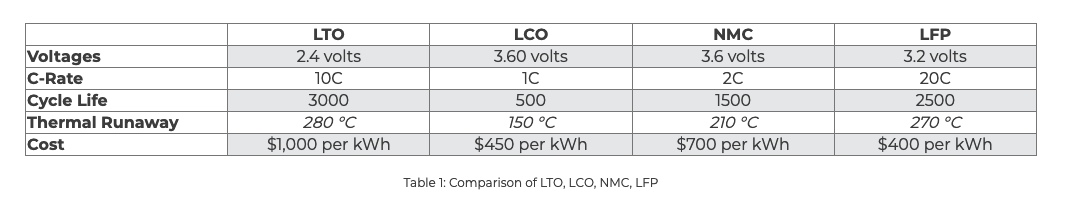

Battery cathode: The cathode is the positive electrode. This is where all the different chemistries come into play. The cathode is what determines the overall lithium chemistry. Like the anode, a current collector is combined with the material so the flow of electrons can occur. The cathode is typically combined with an aluminum film. As shown above there are many different chemistries. The key differences between them is temperature at which they react with the electrolyte (thermal runaway) and the voltages they produce.

Battery degradation: The process that reduces the amount of energy a battery can store. Temperature, charge, and discharge voltage, current and the depth of charge and discharge can affect how much a battery’s capacity is reduced over time.

Battery round trip efficiency: The percentage of remaining energy stored after loss is accounted for throughout the storage process. This is the amount of energy remaining to operate the equipment after the battery has been fully charged.

Operational efficiency: The proportion of output gained compared to the resources expended to achieve the results. The focus of operational efficiency is to improve results using the existing resources available.

Nominal voltage: This is the normal electric voltage that we expect to flow through a circuit. The voltage of a battery pack is determined by the number of lithium-ion cells and how the cells are connected (series or parallel).

Charge cycle: A charge cycle is the complete charge and discharge of a battery used to operate forklift equipment. The battery continues through charging cycles until it has reached the end of its life.

Off gassing: A hazard of overcharging a battery. When a battery overcharges, the electrolyte solution can overheat cause hydrogen and oxygen gasses to form. This will increase pressure inside the battery leading to permanent damage.

Absorbent Glass Mat (AGM): batteries are a type of lead acid battery which contain a glass mat separator. This separator absorbs the electrolyte solution between the battery plates like a sponge which keeps the battery water levels down so you don’t have to water them as constant as other lead acid batteries. However, if the battery is overcharged, gas pressure builds within the cell and will cause the battery to dry out and fail.

Current peak: Current peak is the highest volume of current that is capable of being provided from a power source only for short periods. This is typically achieved upon the initial start-up of an electric device.

Cell pack compression: Cell pack compression is the process of applying compression to the outer walls of the calls through the use of a clamping fixture. The compression helps prevent swelling and potential damage to cells.

Vibration resistance: Vibration resistance is the maximum vibration frequency a battery can withstand without taking damage. Tests on industrial vibration tables are required for batteries to receive certifications such as UL listing and other similar safety tests.

Positive active material (PAM): Positive active material is the lead dioxide created through discharging the battery. This process is reversed when the battery is charging.

Lead oxide: Lead oxide is an inorganic compound that accelerates the speed at which combustible material burns. Lead oxide is produced as a battery is discharged.

Positive grid: Positive grids are used to help improve the lifespan of a battery by providing support to containing active material conducting current and transferring it to the terminals.

Float voltage: Float voltage is the voltage continually provided after a full charge has been completed. This continuous flow of current is to help maintain full capacity, as the battery naturally discharges when not in use.

State of Charge (SOC): A LED display that connects to the BMS, providing the end-user a measurement of how much energy is left in the battery.

Self-discharge rate: The self-discharge rate is the internal reaction that results in a loss of energy in a battery cell that sits unused. Self-discharge progressively gets worse as the battery ages having irreversible effects.

Battery operating cycle lifetime: The battery lifespan is the number of completed charge and discharge cycles a battery can withstand. The battery is considered inoperable when the capacity is too low and rendered useless.

Partial state of charge (PSOC): A partial state of charge is when a battery loses its capability to charge, requiring longer charging times. This happens when a battery is left partially discharged, causing lead sulfate to form on the plates that progressively grow larger over time.

Cyclic capability: The cyclic capability is a measurement of the capacity available to a battery compared to the levels at the first charge. The cyclic capability is affected by the chemistry used in a battery.

Overcharging: Overcharging a battery is charging a battery more than its designed capacity. This can create unstable conditions inside the battery, increase pressure, and cause thermal runaway. This can be damaging to the battery, the equipment, and the operator.

Stratification: Stratification is the process that occurs when the acid separates from the water and collects at the bottom of the battery pack. This causes parts of the plates to be exposed to concentrated levels of acid that cause damage.

Charge acceptance rate (CAR): A charge acceptance rate is the maximum allowed voltage that a battery will allow a charger to provide a charge. A battery will charge at its maximum allowed rate as long as the power supply equals the CAR.

Effective capacity: Effective capacity is the ratio between the true capacity a battery can reach and the rated capacity the battery is advertised for.