If you rely on forklifts to run your business, you know how important it is to supply your fleet with the right batteries.

When it comes to electric forklifts, the two types of batteries most often preferred are lead acid and lithium-ion. Choosing between the two is an important decision that can affect your company’s efficiency and bottom line.

Whether it’s an entire fleet of forklifts, or just one, it can be difficult determining which type of battery to purchase. If you have been using lead-acid batteries for years, switching over to lithium-ion requires research and analysis. After all, forklift batteries are an investment that have a direct impact on your business’ daily operations.

For some, selecting lithium-ion or lead-acid batteries is simply a matter of looking at the price tags. But, there’s much more you should look for in a battery when determining which is best for your operation.

Pro Tip: Click the image of the eBook to get a free copy of Lithium-ion vs Lead Acid forklift batteries.

Here are key elements to consider when making this important business decision:

- Your fleet requirements

- How you operate

- Your electric battery options

- Service life of the battery

- Amount of maintenance required

- Run time of each battery charge

- Energy efficiency

- Safety concerns

- Upfront and long-term costs

By assessing each of these factors, you can better gauge which type of battery provides the most value for your forklift fleet.

Your Requirements

Before deciding which electric forklift battery is best for your business, you’ll need to collect some information to ensure you’re getting the most out of both the forklift and your battery.

For example, here are some requirements to consider:

- What voltage of battery do you need? Forklifts use either a 36 or 48 volt forklift battery, so you’ll need to confirm which battery voltage your forklifts require.

- What is the size of your battery compartment? Measure the compartment your battery sits in - not the old battery.

- What is the best amp hour capacity? Getting the ideal amount of power out of your battery is important, so you’ll need to assess your charge and discharge habits to understand what capacity is best for you.

- What is your forklift battery weight minimum? Placing an underweight battery into a forklift can lead to stability and work safety issues.

A forklift dealer or a battery manufacturer can help you determine which battery meets these, and any other specifications.

Your Options

Once you have determined your basic requirements, it’s time to look at your options more closely. Commercial forklifts generally are powered by either:

- Lead acid batteries

- Lithium-ion batteries

Most widely used, lead acid batteries are liquid filled and come with a removable top that creates electricity when a chemical reaction occurs between the lead plates and sulfuric acid. Invented in 1859, this type of battery has greatly improved since then, but still presents some challenges for forklift operators which will be discussed below.

Lithium-ion batteries, on the other hand, represent the newer technology of the two. First commercially introduced in 1991, lithium-ion batteries are commonly used today in smartphones, tablets and electric vehicles. They’re also becoming more widely used in airport ground support equipment and warehouse equipment, such as forklifts.

Lithium Iron Phosphate (LFP) is one of the most popular chemistries for the material handling industry. LFP is more compact and energy dense than lead acid, and the cells are sealed shut and require no water maintenance.

Service Life

You’re making a big investment. You want to make sure you get the most for your money. That’s why the overall lifespan of your battery matters.

Which type of battery a company uses determines how often workers will need to replace it - an important factor when looking at the total cost of forklift battery ownership. Lead acid and lithium-ion batteries each feature different lifespans. The average service life for each is:

- Lead acid: Between 1,000 and 1,500 cycles

- Lithium-ion: Between 2,000 and 3,000 cycles

Why do these life cycles matter? The longer life cycle a battery has, the less frequently it will need to be replaced. This is a major factor when budgeting for battery maintenance and replacement.

Maintenance Time

As mentioned above, the life of a battery can be severely impacted if not properly maintained. But, maintenance time can be costly.

As you look into which type of battery is best for your operation, you’ll want to consider the level of forklift battery maintenance required.

To maximize service life, certain measures should be taken for both lead acid and lithium-ion batteries. However, lead acid batteries require more care. Here are a few examples of how:

- Cell balancing: Lead acid batteries require equalizing, or cell balancing to counteract sulfation and acid stratification. Sulfation can reduce the overall capacity of the battery and can even render the battery unserviceable in some cases. Acid stratification describes the acid becoming more concentrated toward the bottom of the battery, which makes the battery appear more charged than it actually is. The cell must be rebalanced, and this must be done every 5 to 10 charging cycles. Lithium-ion batteries, on the other hand, automatically perform cell balancing when they are charged to 100%.

- Fluid levels: Lead-acid forklift batteries must have a correct water level in them to work at their best. Approximately every 10 charges, workers must “water the batteries,” or top them off. This can be a messy and tedious process - even dangerous if not done correctly. This can also be time-consuming in large fleets. Lithium-ion batteries do not require a battery watering system.

- Temperature: At higher temperatures, lead-acid batteries lose cycles and have a shorter lifespan. That means extra care must be taken when storing and using these types of forklift batteries. Lithium-ion batteries, on the other hand, don’t suffer as much from the effects of extreme temperatures.

Run Times

This is an important factor to consider when looking for an electric forklift battery. How long a battery lasts during day-to-day operations - or their run times - directly impacts the efficiency of your business.

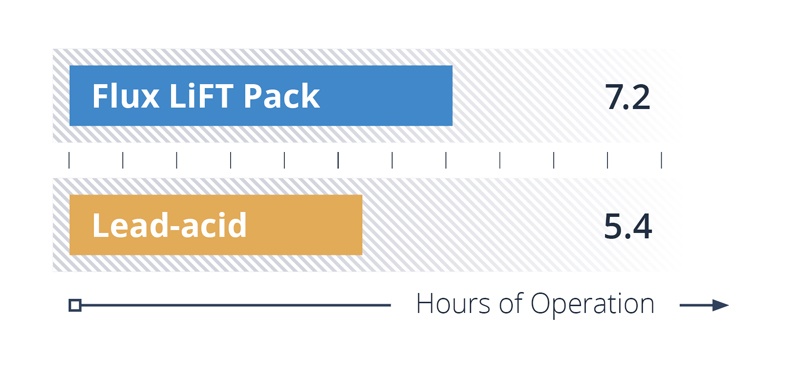

On an average day, lithium-ion battery packs typically feature a run time of between 7 and 8 hours whereas lead acid batteries feature a typical run time of between 5 and 6 hours. However, there is far more to consider when addressing run times.

When the battery must be recharged, lead acid batteries take about 8 hours to fully charge. Then, they must cool down for another 8 hours. This charging process should not be interrupted. That means, over the span of one day, a lead acid battery can only be used for one shift.

That can be a substantial issue for multi-shift, 24-hour operations, which must rely on three lead acid batteries per forklift to keep production flowing.

Lithium-ion batteries, on the other hand, only take about an hour or two to fully charge, and can be “opportunity charged.” That means you can charge the battery - even when it’s attached to the forklift - in between shifts or during breaks.

Energy Efficiency

As a business owner or fleet manager, you understand the importance of energy efficiency. Not only does the amount of energy you use in your operations affect your budget, it also affects your carbon footprint as a business. And today, more and more companies are placing an emphasis on cleaner and more environmentally-friendly energy.

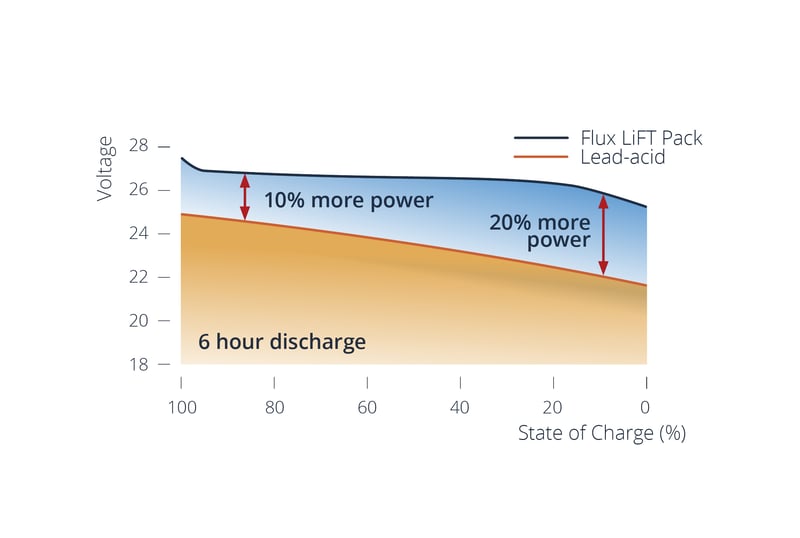

Lithium-ion batteries hold and sustain more power. Lead acid batteries, on the other hand, lose amps when charging, discharging and even sitting idle. Once they begin discharging, forklifts can become sluggish because the voltage inside a lead acid battery drops at an increasing rate.

Lithium-ion batteries maintain a constant voltage throughout the discharge cycle - leading to as much as 50% energy savings when compared with a lead acid battery.

Safety Concerns

Any time you’re looking to make a major investment in your business, equipment safety concerns are always a top priority.

Both lithium-ion and lead-acid batteries are driven by powerful chemicals, so it’s important to consider the safety aspects of each before choosing which type of battery will power your fleet of forklifts.

Lead acid batteries are made from toxic lead and sulfuric acid. This means:

- They must be watered weekly, which can increase the risk of spills.

- They generate a lot of heat when charging, so a temperature-controlled and properly vented room is necessary.

- There is a risk for explosive gas leaks when they reach the top of their charge.

Lithium-ion batteries are made from stable lithium-ion chemical combinations and are completely sealed, so there is no risk of spills. There is a potential risk, however, in that the electrolyte is flammable. Lithium-ion batteries also can produce a corrosive gas if a chemical component inside comes in contact with water. However, because they are sealed, the chance of any acid spills or contamination is extremely minimal.

Pricing

Let’s face it - prices matter. And while it can be tempting to only look at the initial price of a battery when purchasing, it’s important to look at long-term costs as well.

Initially, lead acid batteries typically offer lower upfront costs. This can be a major consideration, especially when you’re purchasing multiple batteries for several forklifts.

However, prudent managers know the cost of something goes far beyond that initial purchase price. Several factors impact the true cost of a battery, including:

- Lifespan

- Daily run times

- Number of batteries per piece of equipment

- Operating and maintenance costs (including labor)

- Efficiency gains

- Energy costs

If you only look at the initial purchase price, you likely will see a slight savings when purchasing a lead acid forklift battery. However, when all the items mentioned above are factored in, the overall savings significantly favor lithium-ion batteries.

In our article, How To Choose The Right Forklift Battery, you can see a cost breakdown between the two that shows approximately how much you would spend based on a 5-year period.

Final Considerations

Choosing the best electric forklift battery for your operations can be an extensive process. There are a lot of factors to consider, especially for many businesses weighing a purchase of this magnitude.

As you can see, lithium-ion forklift batteries have an advantage in nearly every category. While they can cost more upfront, if properly maintained, they are far less expensive over the long term.

They also require less maintenance, have fewer safety risks and are much more energy efficient - a win-win for both the environment and the overall efficiency of your operation.