Why Choosing the Right Forklift Battery Charger Matters

Transitioning your forklift fleet to lithium-ion technology delivers some serious benefits. These benefits can include improved uptime & efficiency, reduced maintenance costs, longer operating lifetime, and more. Because you have invested money into electric forklifts, you want to make sure you receive all those benefits. That is why you want to understand what type of battery charger you need for your equipment.

What factors should a customer consider before deciding on the type of forklift charging system?

There are a few factors you should consider before deciding on what type of forklift charging system you will use:

- Battery type

- Battery voltage

- Charging time

- Charging specifications

- Equipment utilization

- Electrical infrastructure

- Physical space for charging equipment

We spoke with battery charger experts from companies like Delta-Q Technologies and Stanbury Electrical Equipment to get insight on what customers should consider before deciding on the type of forklift charging system.

While there are several factors that customers should evaluate, one of the first pieces of consideration would be charge time,” Delta-Q Technologies Director of Business Development, Rod Dayrit explains. “This is important because this will determine how much power your charger will need to provide the battery.”

Understanding your battery pack, its capacity and its rate of charge can help you determine how long it will take to charge up your battery. Once you know how long it will take to charge your battery, you can strategize the charge period to create the most productivity.

Not only is charging time important to understand but knowing about different charging systems and their capabilities is important as well. Different batteries have unique charging requirements. A lead acid battery can not be charged with the same charger as a lithium-ion battery and vise versa. This is due to the fact that each battery charger takes into account, the charge rate and battery capacity and is designed to maximize the battery’s life.

Conventional Battery Charging

A conventional battery charging system is where you remove a battery and place it on a charger at the end of a shift and let it charge to full capacity. This process typically takes 8 to 10 hours. This is a must for lead acid batteries, which also require a cooldown period (an additional 8 hours).

Lead acid batteries also require dedicated charging rooms to contain any potential spills, leaks, or discharge of toxic gasses. The cooldown period means you will need to purchase three lead acid batteries for each lift truck if you run 24/7 operations.

“Unlike other types of chargers, conventional charging systems are ideal single shift applications with a daily duty cycle that require less energy than the capacity of the battery,” states Oliver Stanbury, Owner of Stanbury Electrical Engineering. “This allows the battery to charge overnight in the vehicle.”

Lithium-ion batteries can be charged in a conventional way if it works for your operations, but there are more efficient charging systems that lithium-ion batteries can take advantage of.

Fast Charging

Fast charging takes between 10 and 30 minutes. It is not generally recommended for lead acid batteries. “Lithium cells are capable of

accepting charge faster and more efficiently than lead acid, allowing single battery per vehicle systems to operate in high use multi-shift applications,” Stanbury explained. If lead acid batteries were to fast charge, their cycle life can tremendously decrease and ruin the battery.

Lead acid batteries require a weekly equalization charge. This is where the battery is charged all the way to 100%. Fast charging stations are perfect for 24/7, always on-the-go operations that cannot afford to take time to swap out batteries or let equipment sit idle.

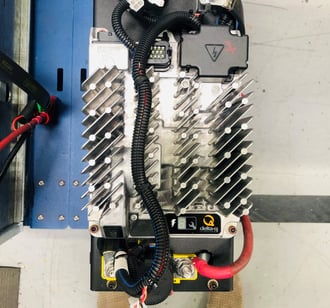

When fast charging, the batteries hover between 40% - 80% SOC and it requires 3 - 4x more amps for charging vs. conventional charging. This may require conversion to accommodate permanent connectors and dual battery cables. Or you might also choose to install fans or vents to keep the battery cooled.

Opportunity Charging

The emergence of lithium battery technology and its low internal resistance has led to the ability to charge at any opportune down time when the equipment is not in use. Opportunity charging takes between 10 and 30 minutes. It is not generally recommended for lead acid batteries. Opportunity charging a lithium-ion battery pack is recommended and actually helps maximize the battery pack’s cycle life.

Like fast charging stations, opportunity charging stations are perfect for multi-shift operations. With opportunity charging, you can keep the battery charged just enough with the sporadic charges to keep things going through your shifts. “This was not possible with older technologies such as traditional lead acid batteries due to their high internal resistance and the dreaded ‘memory effect’,” explained Dayrit.

Unlike fast charging, opportunity chargers can be easier to integrate with existing electrical infrastructure, which makes this type of charger perfect for operations that want to maximize forklift battery usage.

Find the Right Battery Charger for Your Operations

Not all battery chargers are alike and there is an ideal charger for every operation.

- Conventional battery chargers

- Fast chargers

- Opportunity chargers

It is important to consider all charging factors that contribute to your forklift utilization. Ask yourself what kind of charging time expectations you have. Ultimately it comes down to which charger fits your unique operational needs. Do you need to run continuously, or do you have planned downtime?

Understanding your forklift battery charging systems will help you maximize battery life, performance, and costs in your operations.

Power Up Your Forklifts the Right Way—Faster, Safer, Smarter

Enter your email to get a free guide on finding the right charging solution to keep forklifts powered, safe, and performing their best.